Enclosure Types

There are two broad enclosure classifications: open and totally enclosed. Each classification is divided into a number of specific types. The primary types are as follows:

| OPEN | TOTALLY ENCLOSED |

|---|---|

| ODP | TENV |

| WPI | TEFC |

| WPII | TEXP |

| TEAAC | |

| TEWAAC | |

| TEFV |

Open Drip Proof (ODP)

The Open Drip Proof (ODP) motor is designed to be an economical choice for most indoor applications where reasonably clean environments exist. As the name implies, this motor is adequately protected so that water dripping from overhead will not be drawn into the motor.

The Open Drip-Proof should not, however, be used on applications where washdown with hoses is apt to occur or when driving rain, fog or snow will occur.

Weather Protected Type I (WPI)

Weather Protected Type II (WPII)

These motors are specifically designed to withstand more severe outdoor conditions compared to WPI motors.

They are constructed with additional protection against water ingress, typically featuring a drip-proof enclosure that prevents water from entering the motor under normal operating conditions. The air entering the machine will be forced to make 3 abrupt changes in direction of at least 90 degrees.

WPII motors are suitable for applications where there is a risk of exposure to more direct water spray or splash, such as outdoor pumps, compressors, and equipment used in damp or wet environments. Their design enhances reliability and longevity in challenging outdoor settings.

Totally Enclosed Non Ventilated (TENV)

A Totally Enclosed Non-Ventilated (TENV) motor is an electric motor with a sealed enclosure that protects it from contaminants like dust and moisture.

Instead of internal cooling, it relies on the cooling provided by the driven equipment.

Totally Enclosed Fan Cooled

A Totally Enclosed Fan Cooled (TEFC) motor is designed to prevent the free exchange of air between the inside and the outside of the motor housing, but not sufficiently tight to be termed airtight.

The motor is equipped with an integral fan that blows air over the exterior surface of the frame providing cooling.

Totally Enclosed Explosion Proof (TEXP)

A Totally enclosed machine designed to contain an internal ignition of gas or vapor and prevent it from igniting the surrounding atmosphere.

TEXP motors are constructed with robust materials and design features to ensure they can withstand and contain any internal explosions without posing a hazard to the surrounding area. They are commonly used in industries such as oil and gas, chemical plants, and mining operations where safety is paramount.

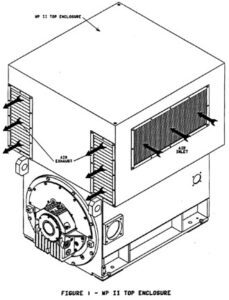

Totally Enclosed Air To Air Cooled (TEAAC)

These motors are designed with a fully enclosed casing that prevents the entry of external contaminants such as dust and moisture.

The cooling mechanism of TEAAC motors involves air-to-air heat exchange within the enclosure, where the internal heat generated by the motor is dissipated to the outside environment through an external cooling fan or blower system.

This design ensures efficient cooling and reliable operation, making TEAAC motors suitable for various industrial applications where protection from environmental factors and effective heat dissipation are critical.

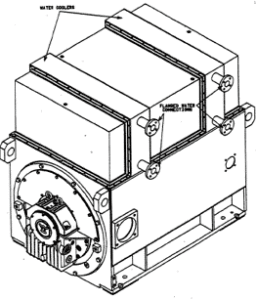

Totally Enclosed Water To Air Cooled (TEWAAC)

These motors are designed for applications where efficient cooling is crucial, typically in environments where air cooling alone may not be sufficient or practical.

TEWAAC motors use a closed-loop cooling system where the heat generated by the motor is transferred to a water circuit inside the motor enclosure. The heated water is then circulated to an external heat exchanger where it is cooled before being recirculated back to the motor.

TEWAAC motors are often used in industries such as steel manufacturing, chemical processing, and power generation, where the operating conditions require effective heat dissipation and protection from external contaminants. They offer higher cooling efficiency compared to air-cooled motors, making them suitable for high-power applications and environments where ambient temperatures can vary significantly.

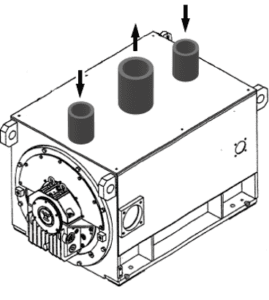

Totally Enclosed Forced Ventilated (TEFV)

A Totally enclosed machine that requires an external source of air to be forced into the inlets and out the exhaust outlets.

The method of forced air used will be determined by the customer.